Injection moulding design and style companies play a crucial part in reworking ideas into higher-good quality plastic areas Prepared for mass manufacturing. No matter whether you happen to be producing a great by yourself or strengthening a preexisting component, Experienced style and design providers maintain your moulded components are successful to produce, Price tag-efficient, and satisfy general performance anticipations.

Exactly what are Injection Moulding Structure Services?

Injection moulding style companies require the look, engineering, and planning within your part or product especially for the injection moulding course of action. This involves from initial 3D modelling and CAD (Laptop-Aided Style) drawings to prototyping and finalising mould style and design. The aim is usually to establish a design that truly works flawlessly with injection moulding machinery while sustaining operation, toughness, and aesthetic appeal.

Vital Features of the Design Process

Quite a few variables should be thought of when creating for injection moulding:

Material collection: Picking out the right plastic is important. Different polymers supply one of a kind properties, such as power, versatility, warmth resistance, or transparency.

Wall thickness: Uniform wall thickness helps prevent challenges like warping, sink marks, or incomplete mould here fills.

Draft angles: Together with slight angles inside of style and design can help areas eject quickly inside the mould without having injury.

Ribs and managers: These functions increase power and assistance to pieces with no growing product usage or excess weight.

A very well-developed aspect not only increases effectiveness but also minimizes generation prices and cycle times.

The worth of Pro Designers

Working getting an seasoned injection moulding layout crew guarantees your solution is prepared for economical manufacturing. These experts watch the complexities of toolmaking, creation machining, and supplies science, and In addition they will help refine your style to circumvent highly-priced mistakes in the future.

Providers like Australian Consolidated Plastics offer full layout-to-generation expert services. Their in-household crew employs Innovative software package to type precision equipment and dies, ensuring each individual part meets tight tolerances and high-quality standards. This entire-services technique will save time, increases accuracy, and accelerates the perfect time to market.

From Prototype to Creation

Structure providers can cause prototyping To judge variety, fit, and performance before complete-scale production commences. This enables purchasers to differentiate and fasten challenges early, conserving equally time and funds In the long haul.

Conclusion

Injection moulding structure expert services can be quite a critical phase within producing journey. By investing in sensible, efficient layout, companies can make certain their plastic parts are production-ready, Value-helpful, and designed to final. With the best structure husband or wife, your idea could develop into a current market-All set actuality.

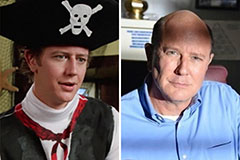

Judge Reinhold Then & Now!

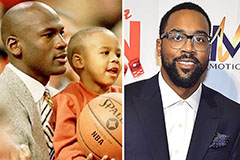

Judge Reinhold Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!